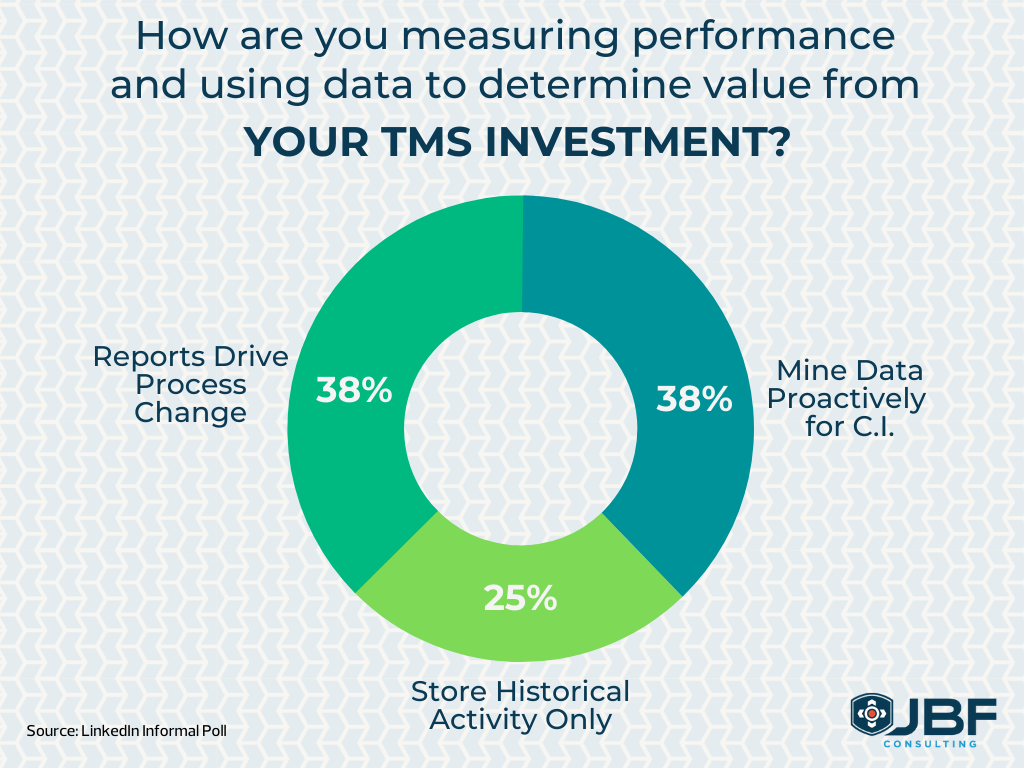

I recently conducted a brief poll on LinkedIn to try to get a sense of what folks that have made investment in TMS (either upgrades or net new) are doing with data collected.

In our experience the spectrum of what shippers do with the new power of data ranges from simply storing it to proactively searching for continuous improvement. Leaders are mining the data and strive to uncover opportunities to improve operations and service, reduce cost, and realize increased value.

I was pleased to see that three-quarters of respondents are at least using system outputs to drive process change. Presumably these folks are tracking KPIs and trends and are taking action upon them.

“Stewardship means taking ownership of the investment you have made and ensuring that solution quality decay does not occur.”

Nearly 40% of respondents are mining the data to uncover untapped opportunities in the transportation and distribution network; lane mode/carrier changes, pool points/cross docks, zone skip, aggregations, multi-stops, terms conversions, the list goes on.

The takeaway here is that there is so much power in the data that to ignore it is like not using all the safety features in your new automobile.

We at JBF have written and talked about TMS post-implementation stewardship for some time now (see below).

Stewardship means taking ownership of the investment you have made and ensuring that solution quality decay does not occur.

In our experience, clients that do not take active ownership after Go-Live will see the quality of their investment deteriorate over time due to lack of data management discipline, adherence to procedure, oversight of the full capabilities of the technology, or just plain old ‘attention has been turned elsewhere’.

"Best in class TMS users regularly ensure that specific people, organization, and processes are in place to maximize use of a valuable asset."

Best in class TMS users (or any technology for that matter) regularly ensure that specific people, organization, and processes are in place to maximize use of a valuable asset.

Leaders remain engaged and deliver ‘leveraged’ value by using more of the software functionality and capability to provide high value-added analytics like modeling, network design, operations analytics, and post-implementation continuous improvement.

Take ownership to ensure your return on investment.

Dennis Heppner is a Principal at JBF Consulting. Dennis’ expertise in transportation, logistics and supply chain operations, and third-party providers spans 25+ years. His experience is broad-based, spanning entire supply chains, including business process redesign, sourcing, distribution network design, transportation management, distribution operations, outsourcing selection, and business strategy for major manufacturers, distributors, retailers including eCommerce, and service organizations.

About JBF Consulting

Since 2003, we’ve been helping shippers of all sizes and across many industries select, implement and squeeze as much value as possible out of their logistics systems. We speak your language — not consultant-speak – and we get to know you. Our leadership team has over 70 years of logistics and TMS implementation experience. Because we operate in a niche — we’re not all things to all people — our team members have a very specialized skill set: logistics operations experience + transportation technology + communication and problem-solving skills + a bunch of other cool stuff.