Recent years have witnessed a cascade of disruption across the shipping industry. This rollercoaster ride has impacted every facet of maritime operations, compelling companies to rethink entrenched strategies and operational models.

Significant events include:

- Global supply chain disruptions – COVID-19 pandemic and port congestions

- Geopolitical tensions – trade wars, sanctions and conflicts (Russia/Ukraine, Yemen, Iran/Israel)

- Environmental regulations – IMO 2020

- Labor issues – strikes and labor shortages

- Infrastructure challenges – Suez Canal blockage and Panama Canal drought

The interconnected nature of global supply chains means that a disruption in one zone can have far-reaching impacts across the entire network. Companies must adopt a proactive, global lens to anticipate and mitigate risks both at home and in other parts of the world. For that, robust supply chain risk management is necessary.

What is Risk Management?

Risk management is the process of identifying, assessing, and prioritizing risks, followed by the coordinated application of resources to minimize, monitor, and control the probability and/or impact of adverse events. Organizations that master risk management take an active approach that enables companies to safeguard continuity and uncover growth opportunities even amid uncertainty.

Risks can be categorized into the following key types:

- Natural Disasters: Earthquakes, hurricanes, floods, and long-term climate change impacts

- Geopolitical: Trade wars, armed conflicts, political instability, regulatory changes, customs and border issues

- Technological: Cyberattacks, technology failures, data breaches, and the challenges of adopting new technologies

- Economic Instability: Currency fluctuations, credit risks, cost increases, demand volatility, changes in consumer behavior, and competitive pressures

- Operational: Process failures, logistics and transportation issues, human resources disruptions, dependence on single suppliers, financial health of suppliers, suppliers’ compliance with regulations, and sourcing challenges

"The interconnected nature of global supply chains means that a disruption in one zone can have far-reaching impacts across the entire network."

Leveraging Technology for Supply Chain Resilience

Leading shippers tailor their risk management strategies to their specific needs, often combining elements from multiple frameworks and adapting them to their unique contexts. This customization results in variations in how risks are categorized and managed, but the underlying principles generally align with the broad categories mentioned above.

Historically, risk identification has relied on manual sources: market intelligence, port authority updates, carrier advisories, and internal communications. Monitoring and assessment were similarly manual using spreadsheets and manual tracking of carriers, vessels and containers, which often led to delayed insights and reactive responses.

For shippers operating in relatively stable or low-risk markets, manual risk management may still be feasible, but for many shippers, today’s interconnected supply chains demand a more agile, automated and proactive method to identify, quantify, and respond to risks. This is where supply chain risk management (SCRM) software comes into play.

Modern SCRM platforms are comprehensive digital solutions that streamline risk identification, assessment, monitoring, and mitigation. These tools leverage real-time data, including geopolitical events, weather disruptions, port congestion, and supplier performance, along with predictive analytics and artificial intelligence, to deliver actionable insights.

With enhanced visibility, automation, and scenario planning, SCRM platforms accelerate response times, minimize operational and financial risk, and strengthen overall supply chain resilience. These tools also enhance cross-functional collaboration, streamline compliance with evolving regulatory and ESG requirements, and empower organizations to base decisions on real-time, data-driven actionable insights. Modern solutions are designed to integrate effortlessly with TMS, WMS, ERP, and visibility platforms through direct connections or APIs.

"...for many shippers, today’s interconnected supply chains demand a more agile, automated and proactive method to identify, quantify, and respond to risks."

A Strategic View of Leading SCRM Solutions

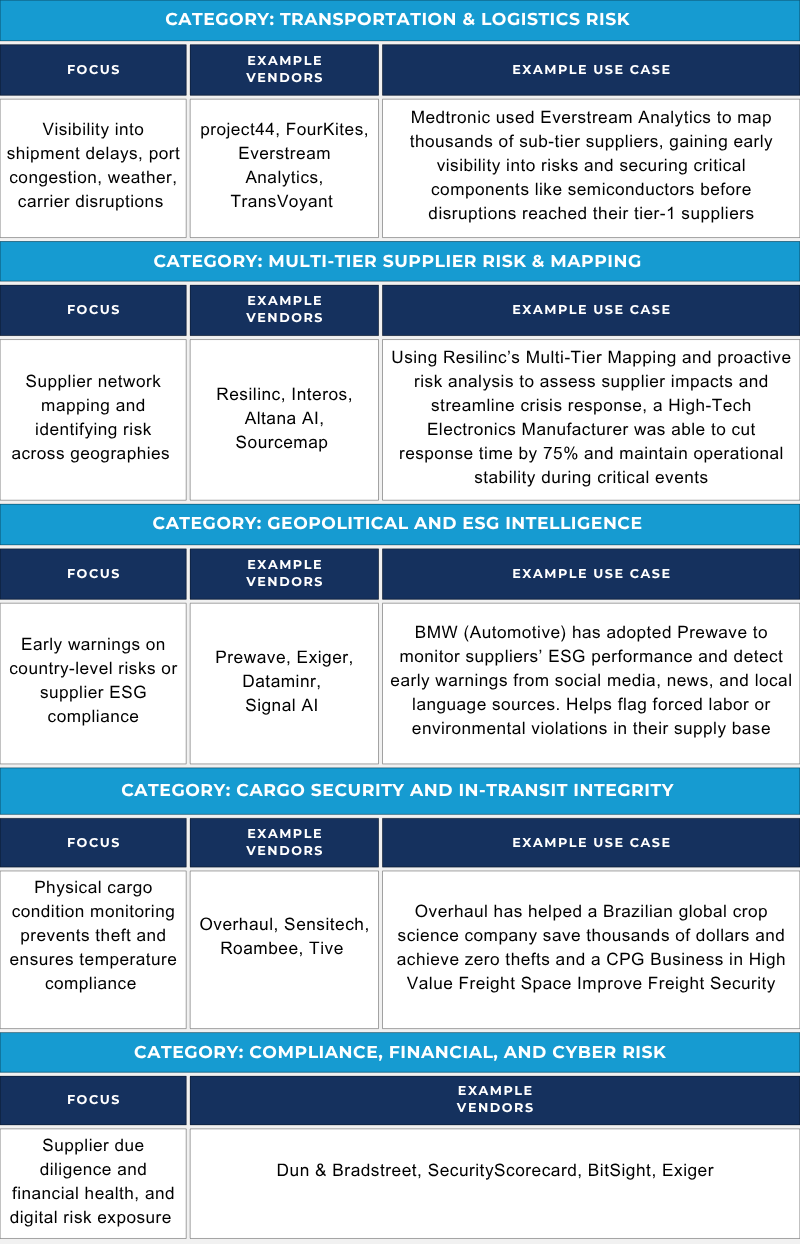

The supply chain risk management technology landscape includes a wide range of providers, each specializing in different dimensions of supply chain risk. For strategic decision-makers, it’s valuable to understand the primary focus area and leading innovators in each category.

Although some providers span multiple categories, this framing highlights each platform’s primary domain, helping organizations align technology investments with their most critical risk exposures.

Navigating SCRM Implementation: Key Considerations

Effective system implementations begin with internal alignment on priority risk domains, where visibility gaps exist, and what level of investment is justified based on their current and future strategic objectives. Not every company requires a SCRM platform right away, and the decision to move forward should be grounded in clear operational priorities and business needs, not just technology availability.

Deploying SCRM software, as with any major technology initiative, requires careful planning. Key factors include:

- Integration Readiness: Evaluate the complexity and scope of integrations with ERP, TMS, WMS, and supplier systems.

- Time-to-Value: Anticipate the adoption curve. It can take time to onboard teams, configure alerts, and realize full benefits.

- Data Quality: Having clean, structured, and timely data is essential for effective risk modeling and actionable risk insights.

- Multi-Tier Supplier Visibility: Assess and address gaps in visibility beyond tier-1 suppliers. Mapping tier-2 and tier-3 suppliers often requires time, supplier cooperation, and third-party support.

- Business Case: Develop a clear, measurable business case focused on specific risk mitigation outcomes and operational improvements with measurable ROI directly linked to strategic objectives.

Strategic Imperatives for Supply Chain Risk Management

As global supply chains face increasing disruptions, organizations are moving from reactive to proactive and from isolated to collaborative. While manual approaches may suffice for those with limited exposures, digital tools offer a path to improved visibility, resilience, and responsiveness.

There is no one-size-fits-all approach to risk management. Strategies must be tailored to industry dynamics, geographic footprint, and supply chain maturity. Organizations should begin by assessing their current risk exposures, pinpointing critical gaps, and considering whether technology, such as risk management software, can support a more effective and scalable strategy.

If you’re ready to build a risk-resilient, future-ready supply chain, contact JBF Consulting for a strategic assessment tailored to your business.

About the Author

Hugo Perez is a seasoned Solution Architect with over 20 years of experience in the transportation and supply chain industry. Fluent in English and Spanish, he specializes in designing, modeling, and implementing logistics solutions for complex supply chain networks. Hugo holds a Project Management Professional (PMP) certification, which underscores his expertise in project management, application configuration, and business process architecture, serving prominent multinational corporations and major industry players.

FAQs

Supply chain risk management is the process of identifying, assessing, and mitigating risks that can disrupt operations. It is crucial because global supply chains are highly interconnected, meaning disruptions in one area can impact the entire network. Effective SCRM safeguards continuity and enables businesses to uncover growth opportunities amid uncertainty.

Key risks include:

-

Natural disasters: earthquakes, hurricanes, floods, climate change

-

Geopolitical risks: trade wars, armed conflicts, political instability, sanctions

-

Technological risks: cyber attacks, technology failures, data breaches

-

Economic instability: currency fluctuations, demand volatility, cost increases

-

Operational risks: logistics failures, supplier non-compliance, human resource disruptions

Modern SCRM platforms use real-time data, predictive analytics, and artificial intelligence to detect and mitigate risks quickly. They integrate with systems like TMS, WMS, and ERP, providing enhanced visibility, automation, and scenario planning. This leads to faster response times, minimized financial losses, and stronger overall supply chain resilience.

Organizations should evaluate:

-

Integration readiness with existing systems (ERP, TMS, WMS)

-

Time-to-value, including the learning curve for adoption

-

Data quality to ensure accurate risk modeling

-

Supplier visibility beyond tier-1 networks

-

Business case with measurable ROI tied to strategic objectives

No. There is no one-size-fits-all approach. Effective strategies must be customized based on industry dynamics, geographic footprint, and the maturity of the organization’s supply chain. Companies should start with an assessment of their risk exposures and decide whether digital tools can support a more scalable and proactive risk management approach.