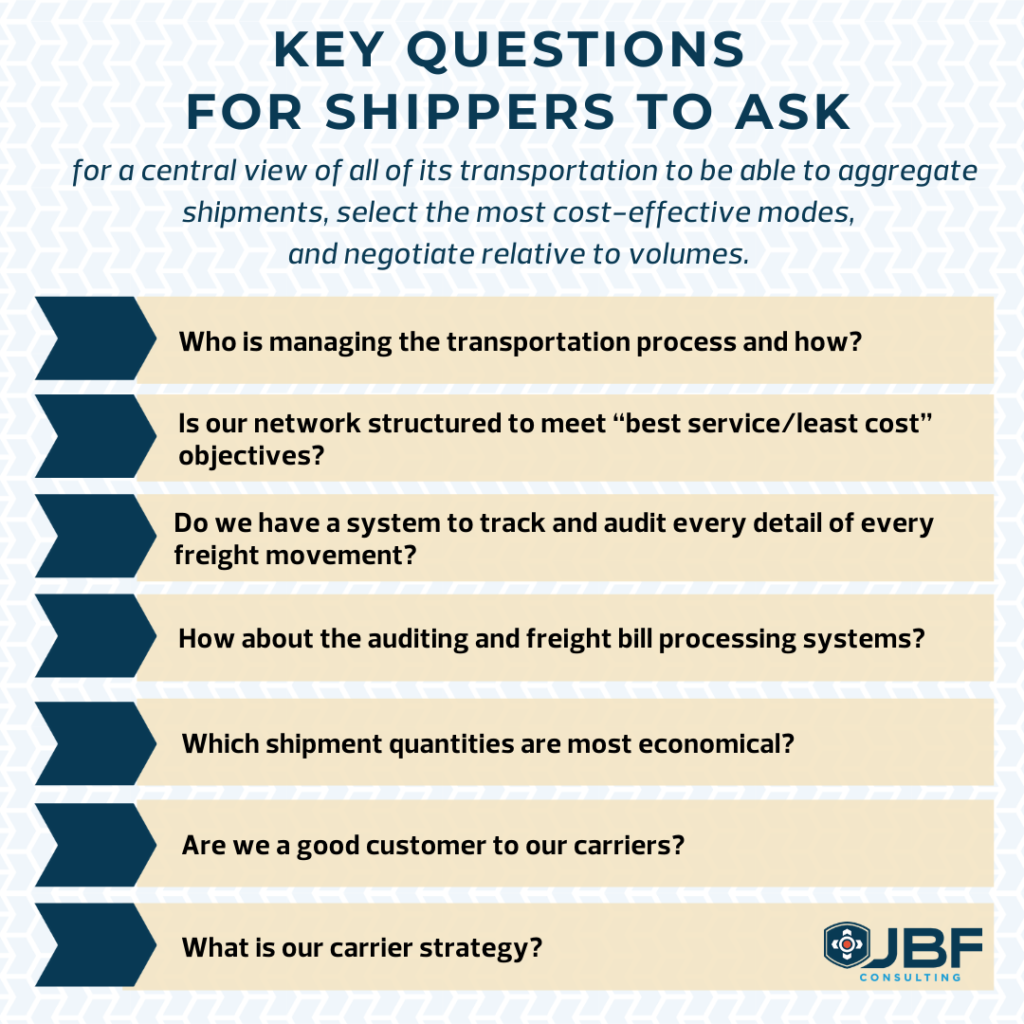

A rule of thumb in transportation is to plan centrally for scale, and execute locally to fulfill unique requirements. A shipper needs a central view of all of its transportation—operating units, locations, customers, shipments, carriers (including fleets), and contracts—to be able to aggregate shipments, select the most cost-effective modes, and negotiate relative to volumes.

Then various operating entities or local sites can execute on a daily basis by aggregating, dispatching, and processing activities. One operating unit might see higher costs, but another may achieve significantly lower costs. And that’s okay.

The ultimate goal is to manage transportation in a way that most benefits the organization overall through the optimal balance between cost savings and better service.

“A rule of thumb in transportation is to plan centrally for scale, and execute locally to fulfill unique requirements.”

Here are a few to consider:

- Who is managing the transportation (inbound, inter-facility, and outbound) process and how?

If vendors route and control inbound transportation, plants or DCs manage inter-facility moves, and outbound is driven by customer service you have little to no chance to standardize processes, enforce routing rules, and minimize cost. Too many chefs in the kitchen results in an inedible meal.

- Is our network structured to meet “best service / least cost” objectives?

Every business we have seen is dynamic. Products, customers, volumes, service requirements all change almost daily. Sure most shippers know peak and off-peak, but are you looking at the big picture holistically, including potential mergers and acquisitions or significant customer changes?

>> Are warehouses, DCs, and cross-docks in geographic locations that fit our business today and tomorrow?

>> Should we consider alternative ports of entry or exit?

>> Are we shipping more frequent, smaller quantities?

>> The transportation skeletal system needs to support logistics vis-a-vis business objectives.

- Do we have a system to track and audit every detail of every freight movement?

If you have not invested in a Transportation Management System (TMS) by now you are already behind your peers. There are dozens, if not hundreds, of technology solutions to manage your transportation. And these solutions are not just for the biggest shippers. SMBs have options to plan, execute, provide visibility, and audit & pay freight invoices.

There is no excuse not to utilize technology.

- How about the auditing and freight bill processing systems?

Are processes and tools in place to effectively match, audit, and approve for payment every freight invoice received?

While we certainly want to pay agreed upon rates and accessorials to our carriers, we don’t want to pay incorrect bills or worse pay bills that don’t belong to us. Too many organizations allow freight invoices to go directly to Accounts Payable who have little to no idea about contracts and carrier services.

Additionally, this is a treasure trove of information, but only if it is accurate and available (see previous point re: TMS technology).

- Which shipment quantities are most economical?

It takes heavy analytical lifting to make sure shipment quantities are not only aligned with customer requirements (OB) or internal needs (IB), but also are cost effective. What was an LTL shipment yesterday, may be multiple parcel shipments today or vice versa. This may require customer service and procurement stakeholder’s input on a regular basis.

“If the only time you talk to your carrier is to beat them up on rates, don’t expect top service.”

- Are we a good customer to our carriers?

Capacity is tight and rates are in the carrier’s favor right now. Of course, this pendulum swings, but irrespective of the current freight market are we offering attractive freight?

Are we doing what we can to make the carrier want to do business with us (minimal detention, clear communications, fact-based negotiations)?

If the only time you talk to your carrier is to beat them up on rates, don’t expect top service.

- What is our carrier strategy—cheap and mediocre service; expensive and top quality; or the best combination of each dynamically selected for each shipment?

All shipments, vendors, and customers are not created equally. Understand which lanes can accommodate a ‘value’ service and those that demand ‘premium’.

There is no value in expediting a shipment only to have it sit on a dock for days. Conversely, you don’t want to impact operations by selecting the ‘slow boat’.

This of course is not an exhaustive list. However, the answers to these questions will enable a shipper to begin to get at the essence of true transportation management. An experienced consulting partner can help you with these and many more questions to build a transportation strategy that fits your business.

Dennis Heppner is a Principal at JBF Consulting. Dennis’ expertise in transportation, logistics and supply chain operations, and third-party providers spans 25+ years. His experience is broad-based, spanning entire supply chains, including business process redesign, sourcing, distribution network design, transportation management, distribution operations, outsourcing selection, and business strategy for major manufacturers, distributors, retailers including eCommerce, and service organizations.

About JBF Consulting

Since 2003, we’ve been helping shippers of all sizes and across many industries select, implement and squeeze as much value as possible out of their logistics systems. We speak your language — not consultant-speak – and we get to know you. Our leadership team has over 70 years of logistics and TMS implementation experience. Because we operate in a niche — we’re not all things to all people — our team members have a very specialized skill set: logistics operations experience + transportation technology + communication and problem-solving skills + a bunch of other cool stuff.