One and Done?

“Don’t worry, Mike. Phase 2 never comes.”

That was the guidance whispered to me by a fellow consultant I was working with at a TMS kick-off meeting. The shipper, a large consumer package goods company, had just acquired a new TMS solution. We were in a conference room discussing project scope and the client’s long-term objectives, and I was concerned about our ability to deliver Phase 2.

The limited scope of Phase 1 was to be followed by a very significant Phase 2, which contained virtually everything NOT included in Phase 1, including the bulk of the value-added elements of the project.

I was worried about integration issues, change management challenges, the scalability of the software, and basic product gaps, all of which would need to be addressed.

How would we be successful?

How will the customer deliver the financial benefits that were promised to senior leadership?

I contemplated the meaning of my colleague’s statement – “Phase 2 never comes.” Was it overly cynical, or was it an accurate depiction of a large-scale, multi-phase enterprise software implementation?

Since then, I have come to the conclusion that, in too many cases, my colleague was correct. The ultimate vision of the TMS becoming the technological foundation from which transportation operational excellence is derived remains a distant goal for far too many shippers.

"The ultimate vision of the TMS becoming the technological foundation from which transportation operational excellence is derived remains a distant goal for far too many shippers."

Are You Underutilizing Your TMS?

If So, You’re Not Alone!

Throughout my career, I have had the good fortune to work with some of the largest shippers and transportation service providers in the world, both as a consultant and as a TMS product manager.

When we talk candidly, an all too common theme amongst these organizations is the belief that they should be getting more from their transportation systems.

A VP at a large retailer told me, “We’re like the proverbial duck. We look smooth on the surface, but underneath, our legs are moving a mile a minute.” For him, part of the vision focused on automating several manual processes, which had yet to be attained.

This retailer is not alone.

In many instances, the vision that originally funded their TMS initiative has only been partially fulfilled as other corporate initiatives have taken precedence. “Phase 2” initiatives, such as implementing new divisions, geographies, advanced functionality, or simply doing a software upgrade, require budget approval tied to a compelling business case and quantifiable ROI. As these are often multi-month—or even multi-year projects—staffed by both internal and external experts, they are expensive and, like any enterprise-level project, inherently risky and subject to delay or cancellation.

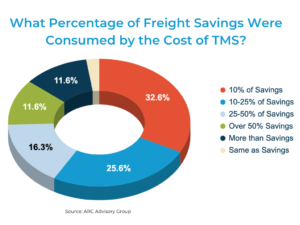

At the time, I found the above chart developed by ARC Advisory quite interesting. It’s based on older information, but I suspect that the underlying results are still valid—and, if anything, the stakes have increased, both with potential savings and costs.

The chart buckets shippers into how much of their freight savings were consumed by the cost of the TMS.

On the positive side, 86% of the shippers surveyed stated that their TMS project paid for itself. However, the costs for TMS software/subscription, services, and ongoing maintenance of the solution are anything but trivial.

Over 40% of respondents stated that those costs ate up more than 25% of the total savings generated by their TMS. I would guess that that number is higher than what was budgeted for the majority of these shippers and may signify that the ROI associated with “Phase 2” never came.

Do TMS Software Providers Deserve Some of the Blame?

To their credit, the Tier 1 TMS software providers continue to invest in and expand on the functional capabilities of their offerings. They have built out holistic transportation management solutions designed to support the entirety of a shipper’s transportation operations, from procurement and tactical planning through payment, covering modes from international air and ocean through parcel and last-mile delivery.

However, the functional richness of these solutions comes with a price.

Implementing new capabilities can be difficult and costly. Additionally, for too many TMS providers, usability has taken a backseat to feature function, which further exacerbates one of the most common issues that derail projects: change management and end-user adoption.

"The vision that originally funded their TMS initiative has only been partially fulfilled as other corporate initiatives have taken precedence."

TMS Implementations Are Too Discrete

You may believe that implementation work around your Transportation Management System never ends, but anecdotal evidence suggests otherwise.

Shippers across all industries suffer from stagnant TMS capabilities, incomplete roadmaps, and unrealized value. The core problem with traditional implementations is that they are discrete in nature – they have a specific start and end. Once the “project” ends or funding has been extinguished, a huge deceleration of capabilities happens. Things stop—and then become stagnant.

Given the considerable expense that freight transportation represents to the shipping community (typically, 3-6% of COGS), transportation professionals need to continuously determine what improvements need to be made to their freight operations, then determine the viability of their current system(s) to meet these needs.

The good news is that today’s TMS capabilities are often underutilized, so there is a good chance that your existing systems’ capabilities can meet these needs.

"The core problem with traditional implementations is that they are discrete in nature – they have a specific start and end. Once the “project” ends or funding has been extinguished, a huge deceleration of capabilities happens. Things stop—and then become stagnant."

How Can You Fight Back?

Here Are Some Ideas…

TMS Audits & Assessments – These are very quick, targeted initiatives that can become the catalyst your TMS needs to catch up. The assessment can be as broad or as narrow as needed but should address the following:

- Achievement relative to expectation (what you thought the TMS would do for you)

- Specific ‘pain points’ the organization believes the TMS is not doing correctly

- Solution or integration gaps that have developed over time (e.g. you added a new business but didn’t make all the necessary changes in the TMS)

- Identify areas of potential cost savings

- Recommend a plan of action!

Create Basic “Health Check” Metrics – These can help you identify immediate, tactical areas of system performance that can address several questions:

- What percentage of the TMS output gets changed by a planner?

- How long does the TMS take to solve my problem, including time spent manually manipulating the output?

- Is it taking longer for the TMS to solve the same amount of input?

- What percentage of total organizational freight spend is controlled in the TMS?

Network and Benchmark – compare with other organizations that use the same TMS platform:

- Oh, you guys do that?

- Oh, it takes you that long?

- Yes, we have the same issue!

- We figured out how to solve that problem…

Create a Strategy – to ‘go beyond’ the original TMS implementation. Focus on how your organization can ‘assimilate’ the TMS:

- Think of your TMS as a child that will mature if you help guide it correctly. If you ignore a child, what happens? (Answer: nothing good!)

- Adopt a continuous improvement mindset – stagnant Transportation Management Systems are far too prevalent and often lead to very costly technology change (e.g. implementing a different TMS and expecting that will solve your problems)

- Leverage a core group of internal SMEs to help guide you, or if you don’t have those… call in the experts to help create and facilitate your post-implementation strategy

Identify and Update Processes – to better align with technology:

- Ensure that your associates have access to data generated by your TMS and regularly review that information both as individuals and as a team, so that they can make better decisions

- Define boundaries for those decisions, including exception management guidelines and escalation paths

- Implement feedback loops for planning and execution functions

- Ensure quality data by establishing robust master data controls, especially for customer/supplier locations data; automate where possible to limit manual work required to maintain the TMS

Bottom Line

To maximize your TMS investment (or any technology investment, for that matter, even a home entertainment system!), you need to understand its capabilities and limitations, introduce these capabilities to meet your requirements, and you must update your systems as your business environment changes. Implementations by themselves don’t address what happens next, so don’t be surprised when “Phase Two” never comes.

To ensure your ultimate vision of your TMS becomes the technological foundation from which transportation operational excellence is derived and one that reaches "Phase 2", consider partnering with JBF Consulting for expert guidance and actionable solutions.

If this topic resonates with you and you'd like to get expert insights, please connect with me on LinkedIn.

About the Author

Mike Mulqueen is the Executive Principal of Strategy & Innovation at JBF Consulting. Mike is a leading expert in logistics solutions with over 30 years managing, designing and implementing freight transport technology. His functional expertise is in Multi-modal Transportation Management, Supply Chain Visibility, and Transportation Modeling. Mike earned his master’s degree in engineering and logistics from MIT and BS in business and marketing from University of Maryland.