In our business, as a logistics technology boutique, failures are critical – but they are also important, and we absolutely cherish what they can teach us. Over the past 20 years in business, JBF has worked on 50 implementations, and there have been many successes - also some failures – along the way.

We define a failure as “an outcome that does not meet the client’s objective or stated expectation.” If we are honest and genuine with ourselves regarding these failures, they can be a tremendous catalyst for innovation and improvement.

Continuous Improvement

At JBF, we have a very simple Purpose Statement: Design Better Outcomes for Our Clients.

For us, it is imperative to continuously assess and re-design our implementation approach to mitigate as much risk as possible and ensure a higher probability of success.

Looking back, the majority of implementation failures tend to occur during the Design phase. The ‘Design’ failures can be categorized into ‘types’ such as Scope, Timeline, Budget, ROI, and User Adoption.

A failure is "an outcome that does not meet the client’s objective or stated expectation".

When we inspect the primary causes of these failures, we keep landing on four key themes:

- Clients have selected the wrong tool (software) for the job.

- Understated the complexity relative to the desired objectives and business requirements, or the requirements were incomplete relative to the client’s true objective.

- Did not allocate enough timeline, budget, and resources to deliver successfully.

- Client was not ready for the magnitude of change.

With these facts in hand, we set out to refine the process to help improve our probability of a successful outcome. What we determined is that to improve the probability of a successful implementation, we actually had to re-design a better approach to vendor selection.

Usually, the best designs are the simplest – K.I.S.S. We also did not want to create ‘project bloat’ just for the sake of revenue, so we wanted to also be efficient and pragmatic to be competitive and also to protect our clients’ budgets.

In the end, we designed an approach that essentially re-sequences common implementation deliverables and pulls these activities forward in the customer journey to be in front of Vendor Selection.

To improve the probability of a successful implementation, we actually had to re-design a better approach to vendor selection.

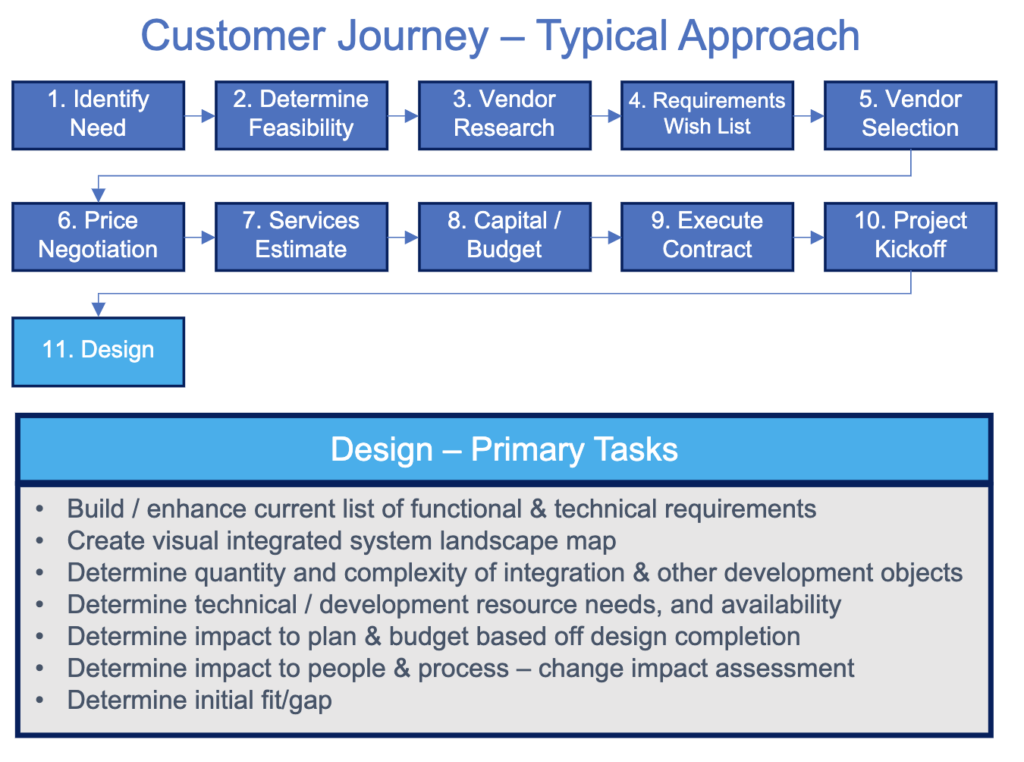

Customer Journey - Typical Approach

This is our perspective of the average Customer Journey with regard to the selection and implementation of technology:

- Identify the need

- Determine feasibility

- Begin vendor research

- Draft a requirements ‘wish list’

- Assemble RFP

- Grade vendor responses

- Vendor selection

- Negotiate vendor pricing

- Ask vendor for implementation cost range

- Complete the capital / budget request with implementation & subscription costs

- Close / complete commercials

- Schedule kick-off

- Begin design:

- Build or enhance current list of functional & technical requirements

- Determine quantity and complexity of integration & other development objects

- Determine technical / development resource gaps, needs, and availability

- Determine impact to plan & budget based on design completion

- Determine impact on people & process – change impact assessment

- Determine fit/gap

After closer inspection, we immediately realized the majority of the failure drivers were contained in #13.

This is typically where we ‘realize’ the failure – and it’s extremely difficult to recover without significant cost and impact.

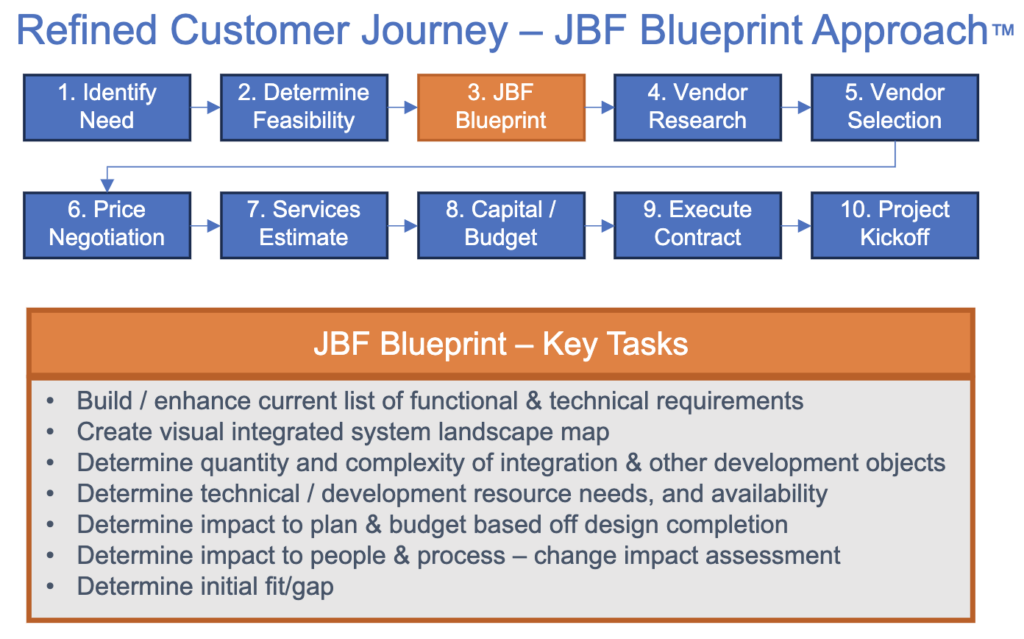

Refined Customer Journey - JBF Blueprint Approach™

In our new model, called ‘Blueprint’, we essentially take Design and move it up to spot # 3 as such:

- Identify the need

- Determine feasibility

- “Blueprint”

➡️ Begin ‘conceptual’ design:

↳ Build or enhance current list of functional & technical requirements

↳ Determine quantity and complexity of integration & other development objects

↳ Determine technical / development resource gaps, needs, and availability

↳ Determine impact to plan & budget based on design completion

↳ Determine impact on people & process – change impact assessment

↳ Determine initial fit/gap

↳ Create vendor short-list

❌ 4. Begin vendor research

❌ 5. Draft a requirements ‘wish list’

6. Assemble RFP

7. Grade vendor responses

8. Vendor selection

9. Negotiate vendor pricing

❌ 10. Ask vendor for implementation cost range

11. Complete the capital / budget request with implementation & subscription costs

12. Close / complete commercials

13. Schedule kick-off

14. Begin design with vendor(s)

- Review requirements

- Detailed design

- Refine fit/gap

By pulling key design activities ahead of vendor selection, we can improve our probability of implementation success and mitigate significant risk – all without adding fees and time to the process.

Reaping the Benefits

The benefits of this approach are tremendous. By pulling key design activities ahead of vendor selection, we can improve our probability of implementation success and mitigate significant risk – all without adding fees and time to the process.

The primary benefits include:

- Improve the probability of selecting the right vendor for our needs.

- Identify key functional gaps ahead of implementation kickoff (we have seen many clients figure out they need additional software & additional vendor selection in the middle of a project.)

- Better aligned organizationally to this initiative and can assess whether we are ready for the change.

- More precise understanding of the project scope, timeline, risks, complexity, and costs.

- Ensure both business and IT resources are available, and we have the proper skills to deliver.

- By figuring out all the ‘hard stuff’ up front, there is high confidence in our budget, costs, and how much of our ROI the implementation will consume – so we don’t have to go back to Finance and ask for more money.

Closing Thoughts

In our estimates, this approach adds between 5-10% to the total implementation costs – but greatly improves the probability of a successful outcome for clients, vendors, and implementation partners.

Additionally, the outputs are essential implementation deliverables – not ‘throw-away’ work for the sake of an insurance policy.

If this topic resonates with you and you'd like to get some solid insights, we invite you to connect with our team on LinkedIn.

About the Author

Brad Forester, CEO of JBF, is a highly recognized senior supply chain leader with over 23 years managing, designing, and implementing freight transport technology, Brad has a unique mix of carrier, shipper, software, and consulting experiences that benefit clients. With functional expertise in Global TMS Programs, Change Management, Organizational Design, and Systems Integration, he has been leveraging these skills to benefit clients since he founded JBF in 2003. Brad has a BA in logistics management from Michigan State University.

About JBF Consulting

Since 2003, we’ve been helping shippers of all sizes and across many industries select, implement and squeeze as much value as possible out of their logistics systems. We speak your language — not consultant-speak – and we get to know you. Our leadership team has over 100 years of logistics and TMS implementation experience. Because we operate in a niche — we’re not all things to all people — our team members have a very specialized skill set: logistics operations experience + transportation technology + communication and problem-solving skills + a bunch of other cool stuff.

ADDITIONAL RESOURCES

Subscribe to the The Digital Logistician

Sign up for our Monthly Email Bulletin

Follow the JBF Company Page on LinkedIn

Download our White Papers & Ebooks