Labor costs in a supply chain can have a significant impact when deciding where your DCs should be located.

According to the 2019 Occupational Employment Statistics published by the U.S. Bureau of Labor Statistics, the lowest median wages for Freight/Stock/Material Movers in the Continental U.S. was in McAllen, TX (near the Mexico border) at $10.45 per hour. The highest cost was in Warner Robins, GA (about 1.5 h south of Atlanta) at $19.80 per hour.

That’s a 90% difference!

When conducting an investment-grade supply chain design (SCD or alternatively called Network Design and Network Optimization) these costs should not be neglected.

Labor Costs for Existing DCs

When conducting an SCD study, we normally obtain the variable operating costs of the existing DCs from my client’s General Ledger. We will sometimes solicit the help of a subject matter expert in the Accounting department to make sure we have the costs properly categorized (fixed/variable and labor/other).

We then calculate a cost per unit by dividing the total variable cost by the total number of units processed over the period of interest (usually a year). This data is directly input into my model.

The assumption is that this per unit cost will remain constant irrespective of the DC throughput. Not entirely accurate, but usually good enough for most SCD projects. Tiered variable costs that vary by throughput can also be used, but this level of detail is hard to obtain and usually not necessary.

In certain cases we have used different variable costs depending on the expected path of a product category through the DC (e.g., manual picking vs. automated picking or picking a spare set of bolts vs. picking a complete lawnmower). This makes sense if the DC stores very disparate products, but be warned that it’s easy to go down a rabid hole when using this approach!

For DCs operated by a 3PL, we have typically been able to use an already available or negotiated cost per unit.

Labor Costs for Candidate DCs

The preferred approach to modeling costs for candidate DCs (i.e., DCs that don’t currently exist) is to identify a DC in the existing network that is representative of the operations intended for the new DC(s).

This does not necessarily have to be the best or the worst operating DC, but one that represents expected operational efficiency (e.g., level of automation, labor organization and picking technology) in the near horizon of the model. This can be an own-company operated or 3PL DC.

For this DC, make sure to split the variable operating costs into two categories: Labor and Other. The variable Labor costs of this DC will serve as the index from which the labor costs for the candidate DCs will be calculated.

For each of the candidate DC locations and the Index DC, calculate the average hourly median wage over the past three years for OCC Code 53-7062 (Laborers and Freight, Stock, and Material Movers, Hand) from the Bureau of Labor Statistics (BLS) data found here.

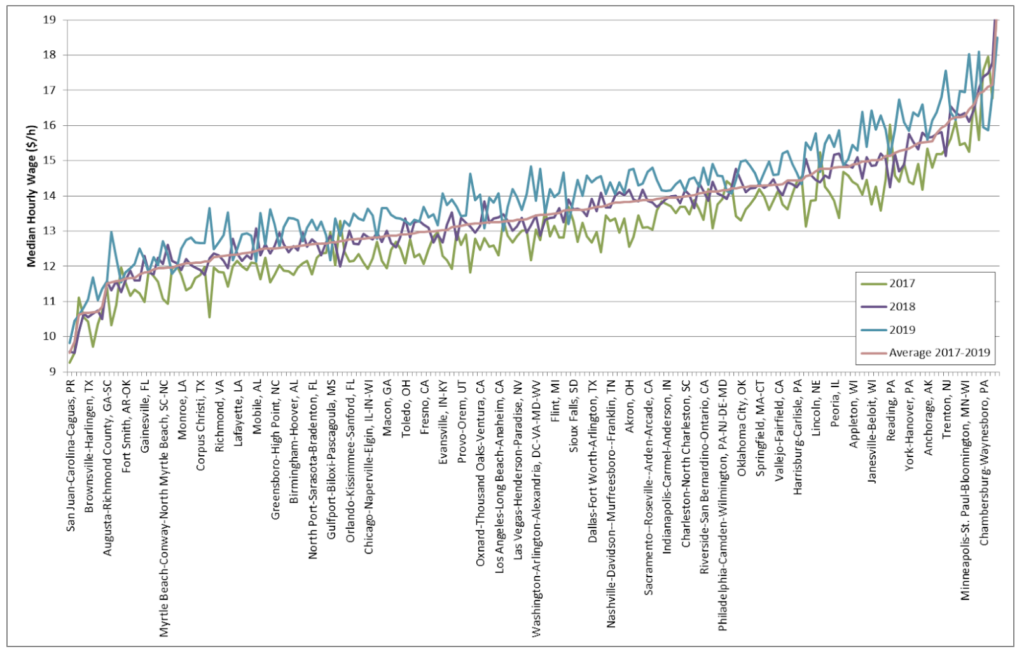

Note that we recommend using the average wage over the past three years, not the value from the current year. This is because there can be a lot of variability in any given metropolitan area from year to year as witnessed in Figure 1.

top 200 Metropolitan Statistical Areas for Freight/Stock/Material Movers employees

(values sorted in ascending order of Average 2017-2019)

Using the data from the current year can lead to erroneous results. Conversely, the data beyond 3 years starts getting a little stale and may not be reflective of reality.

Once we have the BLS benchmark data, calculate the variable Labor cost for each candidate DC as follows:

Variable Labor Cost of Candidate DC =

Variable Labor Cost of Index DC

X BLS Benchmark Wage for Candidate DC

÷ BLS Benchmark Wage for Index DC

Then add the Other costs to the variable Labor cost to get the Toal variable cost. These Other costs are assumed to remain constant from one DC to another. The values are typically much lower than labor and do not vary much from one geographic region to another.

For example:

| Variable Labor cost of index DC = $3/unit |

| Variable Other cost of index DC = $0.25/unit |

| Average hourly median wage in the area of index DC = $10/h |

| Average hourly median wage in the area of candidate DC = $12/h |

| Variable Labor cost of candidate DC = $3/unit x $12/h ÷ $10/h = $3.6/unit |

| Variable cost of candidate DC = $3.6/unit + $0.25/unit = $3.95/unit |

New BLS Data

In the past, we have used OCC Code 53-7062 – Laborers and Freight, Stock, and Material Movers, Hand – as the closest definition of a DC floor employee. The occupation is officially defined as:

Manually move freight, stock, luggage, or other materials, or perform other general labor. Includes all manual laborers not elsewhere classified. Excludes “Construction Laborers” (47-2061) and “Helpers, Construction Trades” (47-3011 through 47-3019). Excludes “Material Moving Workers” (53-7011 through 53-7199) who use power equipment.

In its 2019 data, the BLS has included a new occupation that better defines the role and that we will use in the future when three years of data become available. It is OCC Code 53-7065 – Stockers and Order Fillers – and is defined as follows:

Receive, store, and issue merchandise, materials, equipment, and other items from stockroom, warehouse, or storage yard to fill shelves, racks, tables, or customers’ orders. May operate power equipment to fill orders. May mark prices on merchandise and set up sales displays. Excludes “Shipping, Receiving, and Inventory Clerks” (43-5071), “Laborers and Freight, Stock, and Material Movers, Hand” (53-7062), and “Packers and Packagers, Hand” (53-7064).

Other Labor Costs

For roles that are less dependent on product throughput in a DC, such as data clerks and management, we typically include those as fixed costs and use the value from my index DC.

Here again, we would use a tiered structure if we see a lot of variability in the size of the candidate DCs and want to account for extra or fewer headcounts for these support functions.

Conclusion

In most supply chains, DC labor costs are a significant portion of the total cost. Free and readily available data can be used to help model this factor when conducting a supply chain design study. It will make your model more rigorous and the results easier to sell.

Next Steps

Do you have the right footprint for your network?

Are you looking to reduce costs?

Please reach out to us at brad.forester@jbf-consulting for more information.

Founded in 2003, JBF Consulting is a supply chain execution strategy and systems integrator to logistics-intensive companies of every size and any industry. Our background and deep experience in the field of packaged logistics technology implementation positions us as industry leaders whose craftsmanship exceeds our client expectations. We expedite the transformation of supply chains through logistics & technology strategy, packaged & bespoke software implementation, and analytics & optimization. For more information, visit us at www.jbf-consulting.com